Shop Stories

Limited Operations Today August 3rd

Unfortunately, due to phone and internet outages in our area, we will have limited operations today. We appologoze for the inconvenience. We hope to resume normal operations on Monday’s August...

Limited Operations Today August 3rd

Unfortunately, due to phone and internet outages in our area, we will have limited operations today. We appologoze for the inconvenience. We hope to resume normal operations on Monday’s August...

Before and After: Stainless Steel Laser Cut Bur...

Frequently we are asked to deburr and clean parts that have been laser or plasma cut. This is a common application for the C&M Topline Mr. Deburr machine and good...

Before and After: Stainless Steel Laser Cut Bur...

Frequently we are asked to deburr and clean parts that have been laser or plasma cut. This is a common application for the C&M Topline Mr. Deburr machine and good...

Before and After: Stainless Steel Golf Putters

Process Developed: Machine: Mr Deburr DB300 Two Hours with Angle Cut Triangle 7/8 X 7/8 SF 45 minutes with Angle Cut Cylinder 3/16 X 3/8 P Compound: VF100 with the SF Media, VF150 with...

Before and After: Stainless Steel Golf Putters

Process Developed: Machine: Mr Deburr DB300 Two Hours with Angle Cut Triangle 7/8 X 7/8 SF 45 minutes with Angle Cut Cylinder 3/16 X 3/8 P Compound: VF100 with the SF Media, VF150 with...

Supporting the Future of Manufacturing

C&M Topline is excited to announce our support for Team 973 |The Greybots out of Atascadero High School in Central California. The Greybots are a high school robotics program that is currently...

Supporting the Future of Manufacturing

C&M Topline is excited to announce our support for Team 973 |The Greybots out of Atascadero High School in Central California. The Greybots are a high school robotics program that is currently...

Before and After: Glass and Iron Filled Thermo...

Plastic parts are notoriously difficult o run in a tumbling process. For this part the goal was to remove the mold parting line and impart a matte finish for a...

Before and After: Glass and Iron Filled Thermo...

Plastic parts are notoriously difficult o run in a tumbling process. For this part the goal was to remove the mold parting line and impart a matte finish for a...

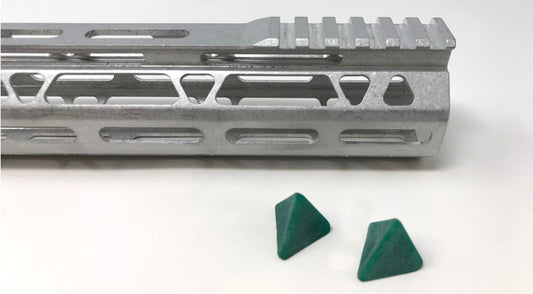

Before and After: Aluminum 6061

This is a very common application and common material for tumbling. Tumbling in our Mr Deburr machine is the most efficient way to prepare CNC machined firearm parts like these...

Before and After: Aluminum 6061

This is a very common application and common material for tumbling. Tumbling in our Mr Deburr machine is the most efficient way to prepare CNC machined firearm parts like these...