Process Developed:

Machine: Mr Deburr DB300

- One Hour with Angle Cut Triangle 7/8 x 3/8 SF ceramic

- Thirty minutes with Angle Cut Cylinder 3/16 X 3/8 Polishing Ceramic

- Compound: VF100

Results:

The blades provided had many hours of use in the field at temperature. The surfaces of each blade were blackened by heat exposure. The process significantly brightened each blade and removed any surface imperfections caused by the combustion process. Ceramic media in a Mr Deburr tank tumbler is ideally suited for processing titanium parts.

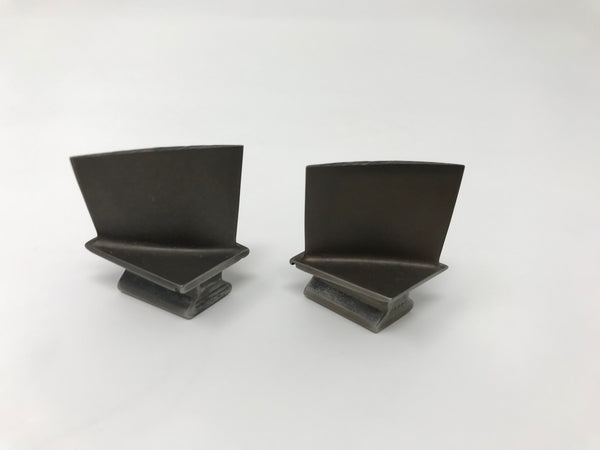

Before

After